Rice Mill Machinery Manufacturer

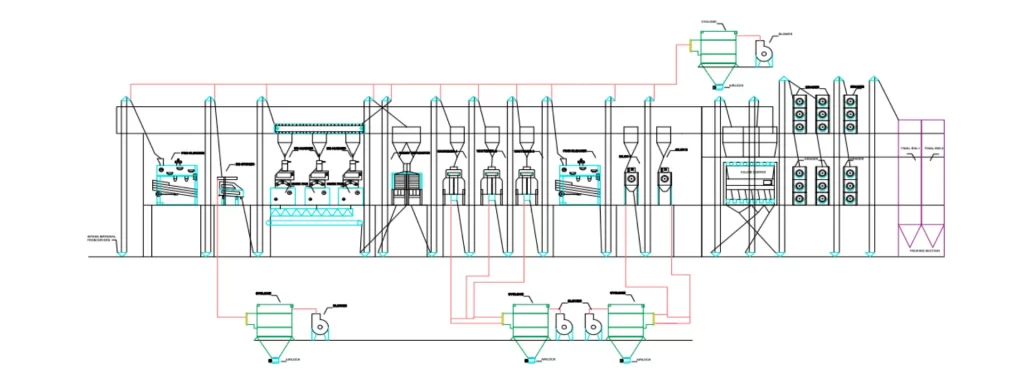

Annapurna Agronics Machinery Pvt. Ltd. is a leading manufacturer and supplier of rice mill machinery in India. we can assist you in Re-engineering your existing Rice mill as well as designing and installation of a new Project envisaged by you. We also assist in providing financial solutions to our valued clients for modernizing their mills. Our rice mill plant are meticulously designed and crafted to streamline the rice milling process, ensuring maximum efficiency and superior quality.

Rice mill machine refers to the equipment and devices used in milling rice to obtain white rice from paddy (unhusked rice). This process involves several stages, including cleaning, husking, whitening or polishing, sorting, and packaging.

Features of rice mill machinery manufacturers in india

- Cleaning: The raw paddy is cleaned to remove impurities like stones, dust, and other foreign materials. This stage often involves using pre-cleaners and designers.

- Husking: In this stage, the outer husk of the paddy is removed to obtain brown rice. Machines like hullers or huskers are used for husking.

- Whitening or Polishing: Brown rice is whitened or polished to remove the bran layer and obtain white rice. This stage involves using rice whitening machines or polishers.

- Sorting and Grading: The milled rice is sorted and graded based on size, shape, and quality. Optical sorters and graders are commonly used in this stage.

- Packaging: The final rice is packaged for distribution and sale. Packaging machinery is used to weigh, pack, and seal the rice into bags or other containers.

- Storage and Handling: After packaging, the rice is stored in warehouses before distribution.

Our Products

The Vibro Classifer MTR is used in the milling of wheat, pulses, rice and other grains milling and processing plants.