Dal Mill Machine Manufacturers

Annapurna Agronics Machinery Pvt. Ltd. is a leading manufacturer, supplier, and exporter of Dal Mill Machine and mini dal mill prices in India. With our commitment to excellence and innovation, we provide high-quality equipment that revolutionizes the dal milling industry. Dal Mill Plant is used to process dal like masar, lentils, mataki, tur, urad, chana, etc. This process include milling, grinding, grading, polishing, monitoring, cleaning, flour making, and removing stones, dust from dal. To get the pure, healthy and best quality dal, buy our dal mill plant at a market leading price. Being a customer-centric organization and one of the best Dal Mill Machinery Plant Manufacturers, Suppliers, and Exporters, we provide excellent quality lentils and pulses and supply them to different cities in India.

Features of Mini Dal Mill Machine:

- Most useful for low cost production

- Offers production of 100 to 125 Kg per hour

- Dal tastes delicious

- Surefire average profit of Rs 500 to Rs 1000 per working day

- Handsome recovery of 72 to 75% of dal

Advantages of Mini Dal Mill Machine

✓ Suitable for processing all types of pulses

✓ Easy to operate

✓ Operates by electric motor / PTO

✓ Recovery of head pulses – 78% to 80% Recovery of broken parts: 2 to 5 %

✓ De husks and splits all pulses with high nutritive value

✓ Special provision for Bengal gram (Chana, chickpeas) by emery roll for de-husking and splitting

✓ Pollution-free operation

✓ Compact size

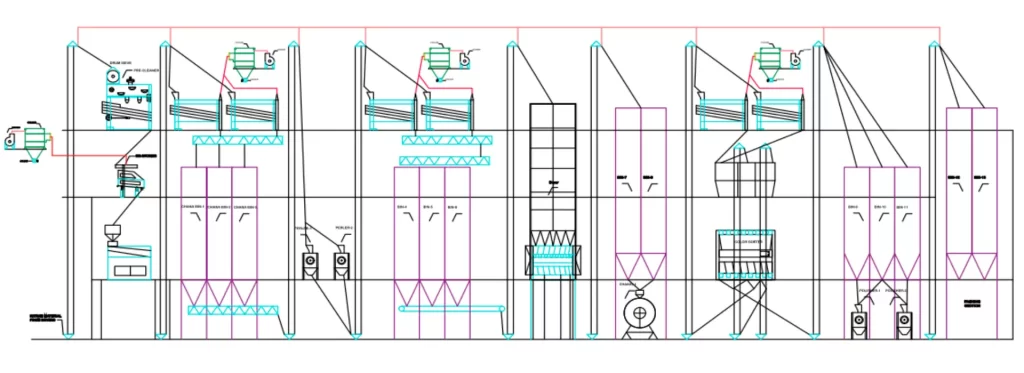

Dal Mill Machine Diagram

| Automation Grade | Semi-Automatic |

| Motor type | Three phase / single phase |

| Recovery of broken pulses | 2 - 5 % |

| Capacity | 100-150 Kg. Per hr |

| Length | 1600 mm |

| Width | 1550 mm |

| Height | 1800 mm |

| Motor Power | 3 HP (2.25 kW) |

| Material | MS |

| Brand | Annapurna Agronics Machinery Pvt. Ltd. |

Our Products

Frequently Asked Questions (FAQs)

What is a Dal Mill Machine?

A Dal Mill Machine is a piece of agricultural machinery used to process dried pulses (such as lentils, peas, and beans) into edible dal, which is a staple food in many regions.

How does a Dal Mill Machine work?

A Dal Mill Machine works by cleaning, de-husking, splitting, and polishing dried pulses. It uses various mechanisms like sieving, grading, and separation to achieve these processes.

What are the key components of a Dal Mill Machine?

The main components of a Dal Mill Machine include a cleaning unit, de-husking unit, splitting unit, polishing unit, and a power source (electric motor or diesel engine).

What types of pulses can be processed by a Dal Mill Machine?

A Dal Mill Machine can process a wide range of pulses including lentils, chickpeas, mung beans, pigeon peas, and more.

What is the capacity range of Dal Mill Machines?

Dal Mill Machines come in various capacities, ranging from small-scale units suitable for farmers and small businesses, to larger industrial-grade machines for higher production volumes.

Is the Dal Mill Machine easy to clean and maintain?

Yes, modern Dal Mill Machines are designed for easy cleaning and maintenance. They often come with removable parts and clear access points for hassle-free cleaning.

What are the benefits of using a Dal Mill Machine?

Using a Dal Mill Machine allows for efficient processing of pulses, resulting in higher quality dal with reduced manual labor. It also helps in minimizing losses and increasing overall productivity.

Can Dal Mill Machines be used for other crops or grains?

While Dal Mill Machines are specifically designed for processing pulses, some versatile models may have provisions for processing other grains like rice, wheat, or maize with appropriate adjustments.